Before we bought her, our pocket cruiser Cheval de Mer had been in the same berth for some 20 years, through two previous live-aboard owners. For most of that time, she has sat with her bow facing into the dock on six permanently spliced mooring lines, which had been specifically created to hold her in position with easy access to a ladder up onto the dock along the starboard side.

We have no protective toe rails on Cheval de Mer, and the mooring lines had been rubbing in the same places for so long, that they had chafed right through the gel coat on the gunwale to the glass fibres beneath. I’ve sealed the worn holes with West System resin, and preventing further damage is on the to-do list.

I had been checking the dockside fittings now and again, and had already doubled-up on two of the lines because they were looking a bit old. Then one winter’s night there was a wind event recorded as 120km/h, so I dropped by the marina next morning to check that all was well. There’s a short mooring line that is used to keep her close to the ladder, but the land-side connection isn’t really visible as it is hidden under the dock. That morning I found the mooring line floating free, with the rope eye and metal thimble worn completely through.

Clearly, I was overdue to replace all the lines, but the reason that I hadn’t done it properly yet was that I didn’t want to just replace them ‘as is’. My preference is to be able to pop out for a single-handed sail now and again, and so far I haven’t done that on Cheval de Mer because of the difficulty of reversing out of the tight corner in which she is berthed, an action that really needs two people, one to steer and the other to fend-off. I wanted to make up new lines which would allow us to berth her stern-to, giving me the opportunity to simply motor out of the berth whenever I wanted to. In case you’re wondering, berthing in reverse will be much simpler than departing in reverse, due to the configuration of the pontoons and available hand-holds.

We waited for our chance when the wind was low and the tide was slack, so that we could turn her around in her berth while hastily fabricating temporary lines. I had an idea in my head that we would push her out and turn her around by hand, but Bronwyn pooh-poohed that plan and said that she’d simply motor out to sea, turn around, and come back in. Since somebody needed to be on the foredeck to fend off, and somebody else needed to be on shore to work the lines, we borrowed the services of our friend Peter, and thank goodness that we did.

We arrived as planned on a wind-free afternoon at the slack of high tide and started the motor, an old but serviceable Yanmar single-cylinder which thudded reassuringly as Bronwyn backed Cheval de Mer out of her berth. All went well until she was out in the channel and making that tricky first turn, and then the overheating alarm came on. Last time that happened, we ended up with a bilge full of oil, so Bronwyn hastily killed the engine and we completed the manoeuvre by hand, using lines, ironically as I’d originally planned. Luckily there were three adults and a child to help with the fending-off.

We got her around without too much fuss, and then pulled her gently into the berth. As the stern swim platform came gently level with the end of the berth, Bronwyn somehow fell off it and banged both thighs on the concrete dock. It hurt a lot, and resulted in significant and colourful bruising.

While Bronwyn sat quietly and thought nice thoughts, the rest of us juggled the available lines into suitable lengths, and it wasn’t long before we had her nicely positioned. In fact, with the stern swim platform facing the end dock, there’s little need to use the midships ladder at all, you can just step on and off the swim platform whatever the tide. It’s a bit of a mystery why the live-aboard owners chose to keep her bow-to in the first place.

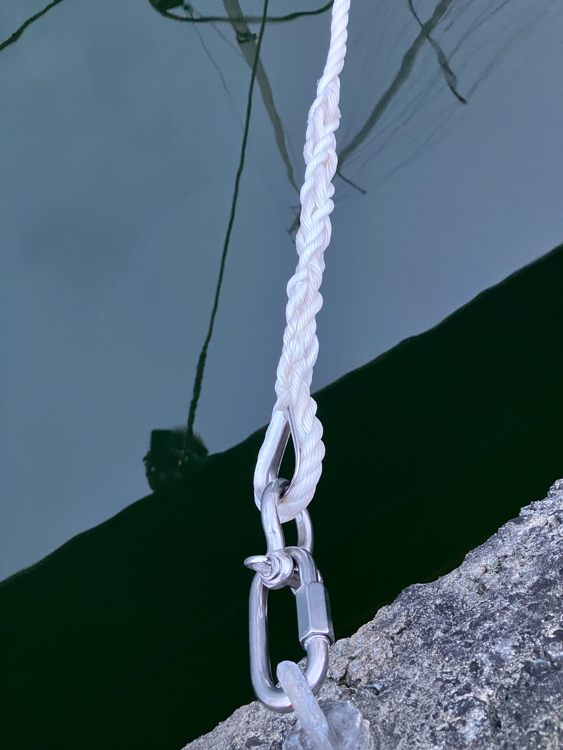

Back at home, I got out a large roll of poly rope, and taught myself to splice an eye. It always seems so complicated when you read about it, but in practice it turned out to be pretty simple to make a slightly amateurish but strong eye in the end of the rope.

As always, practice makes perfect, and over a few weeks I made a full set, complete with new stainless-steel shackles and thimbles for the landward side.

I tied the boat-end in a temporary bowline, so that I had some flexibility in choosing a good final length in all tides and weathers without committing yet to a splice at both ends. Meanwhile, I need to figure out what’s wrong with the raw water cooling pump…